东风卡车440系列油封

We mainly deals in Dongfeng truck accessories (engine/axle/gearbox/cabin), especially Dana axle accessories and Cummins engine parts (4BT, 6BT, 6CT, 6L, ISBE, ISDE, ISLE,ISF2.8, ISF3.8, NTA855, KTA19,KTA38, KTA50, M11, ISM, etc.) with great advantages.

Product Descreiption

The Dongfeng Truck 440 Series Oil Seals are premium sealing solutions engineered for Dongfeng’s flagship 440 series heavy-duty trucks, designed for ultra-demanding applications such as mining, heavy construction, off-road transportation, and long-haul freight under extreme conditions. Built to withstand high torque, severe vibrations, and harsh environmental factors, these oil seals deliver unparalleled durability, leak prevention, and thermal stability. Leveraging advanced materials and precision manufacturing, the 440 series oil seals ensure optimal performance, minimize maintenance costs, and extend the lifespan of critical components in Dongfeng’s most robust commercial vehicles.

Key Applications & Compatibility

- Vehicle Models:

- Dongfeng 440 Series: EQ4450, EQ4350, EQ4250 (6×4, 8×4, 10×4 configurations), and specialized variants for mining and military use.

- Compatible Components:

- Engine: Crankshaft front/rear seals, camshaft seals, turbocharger seals, and valve stem seals.

- Transmission: Heavy-duty input/output shaft seals, transfer case seals, and clutch release bearing seals.

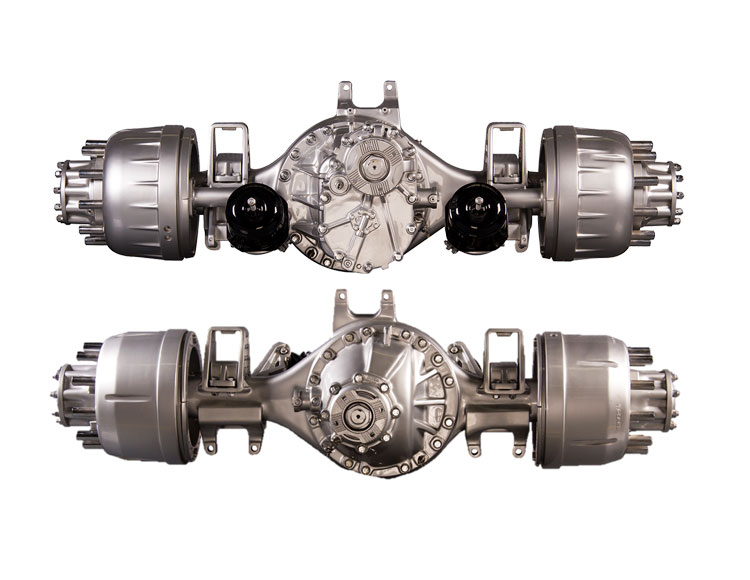

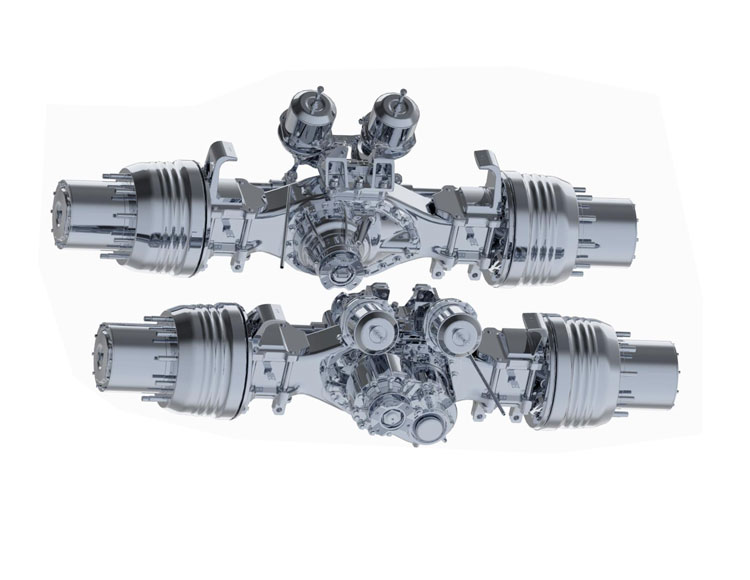

- Rear Axle: Inter-axle differential seals, wheel hub seals, and planetary gear seals.

- Front Axle: Steering gearbox seals, kingpin seals, and suspension pivot seals.

Technical Specifications

- Material & Construction:

- Seal Lip:

- Nitrile Rubber (NBR): Standard option for general-purpose use (temperature range: -40°C to +120°C).

- Fluorocarbon Rubber (FKM/Viton): High-temperature variant (up to +230°C) for turbocharged, high-output engines.

- PTFE (Teflon)-Coated Lips: Ultra-low friction and high wear resistance for high-speed or dry-running applications.

- Metal Case:

- Cold-Rolled Steel (SPCC): Cost-effective and corrosion-resistant for standard use.

- Stainless Steel (SS316L): Optional for marine, mining, or highly corrosive environments.

- Spring: High-tensile stainless steel spring with anti-corrosion coating for consistent lip pressure under extreme conditions.

- Seal Lip:

- Common Dimensions (Example: Rear Axle Inter-Axle Differential Seal):

- Inner Diameter (ID): ~90–110 mm (3.54–4.33 inches).

- Outer Diameter (OD): ~120–140 mm (4.72–5.51 inches).

- Width: ~18–22 mm (0.71–0.87 inches).

- Design Type: Quadruple-lip with integrated dust exclusion lip, pressure relief grooves, and anti-extrusion rings for heavy-duty sealing.

- Performance Characteristics:

- Pressure Rating: Up to 1.5 MPa (218 psi) for high-pressure hydraulic, transmission, and differential systems.

- Speed Rating: Up to 6,000 RPM (depending on seal type and lubrication).

- Temperature Range:

- NBR: -40°C to +120°C (-40°F to +248°F).

- FKM: -25°C to +230°C (-13°F to +446°F).

- Chemical Compatibility: Resistant to mineral oils, synthetic lubricants, diesel fuel, hydraulic fluids, and mild acids.